Lo-Density® Alternative Screwplug Immersion Heater: Rigid Tubular Drywell Heater

Process Heating Co. has developed Rigid Tubular Drywell Heaters to solve the problem of heating viscous products without damage to the product being heated. These heaters can be installed as direct immersion units in tanks and vats as well as distributor trucks, to maintain process temperatures during operation, plant maintenance shutdowns or to increase oil temperatures prior to startups.

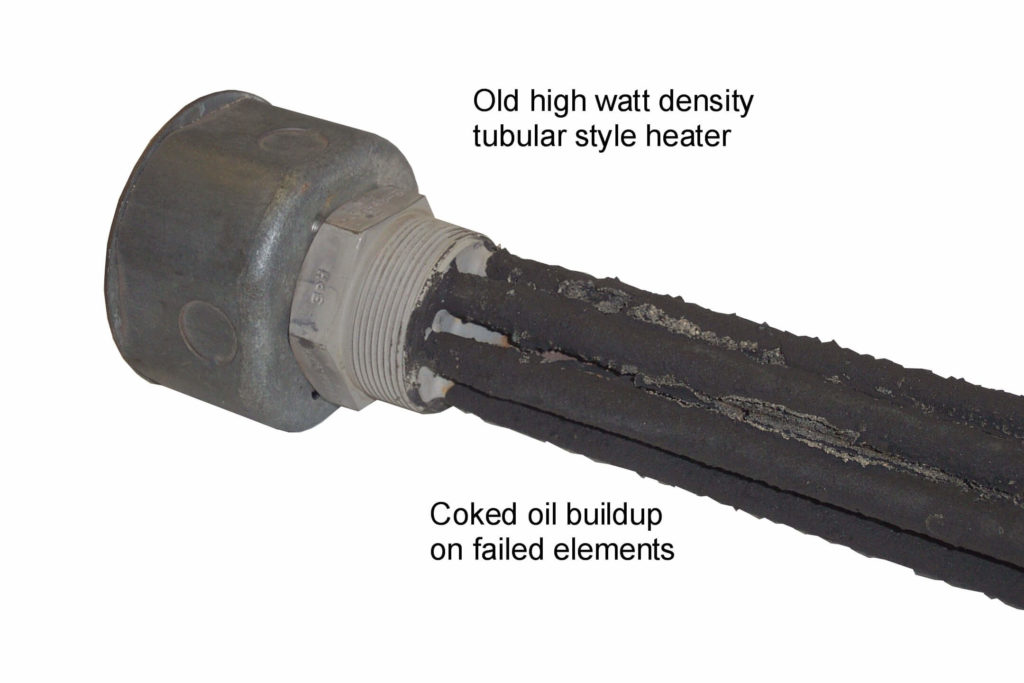

The Rigid Heaters can be installed as new or as replacement equipment for existing metal sheathed style tubular units that have higher watt density designs that result in coking of the oil. Process Heating’s Rigid Heaters ease maintenance with their drywell design, allowing replacement without draining the reservoir, resulting in no machine downtime. The low watt density design reduces damage to the material being heated and build-up on the elements, resulting in longer heater life. These heaters can be equally spaced across the base of reservoirs or around tanks for even heat distribution, eliminating hot and cold sections.

- Can be installed in new equipment or as retrofits in existing tanks/vats/reservoirs

- Maintain temperatures in reservoirs during operation and shutdowns or raise temperatures before startup

- Low element temperatures reduces damage/coking of fluids

- Drywell design allows element replacement without draining the reservoir

- Provides even heat distribution throughout the reservoir

- Extended heater life

- Five year element warranty

- ETL listed

- Quality industrial heating systems since 1947