Lo-Density® Heaters For Biodiesel Products

Whether you need to heat your storage tanks or you want to preheat product before processing, Process Heating Company has the right system for your application. We have over 60 years experience manufacturing electric heating systems with low watt density construction that will not damage the material being heated. These systems feature drywell style elements that allow the internal heaters to be replaced without draining the tank. These electric systems are virtually 100% efficient and carry our exclusive 5-year element warranty.

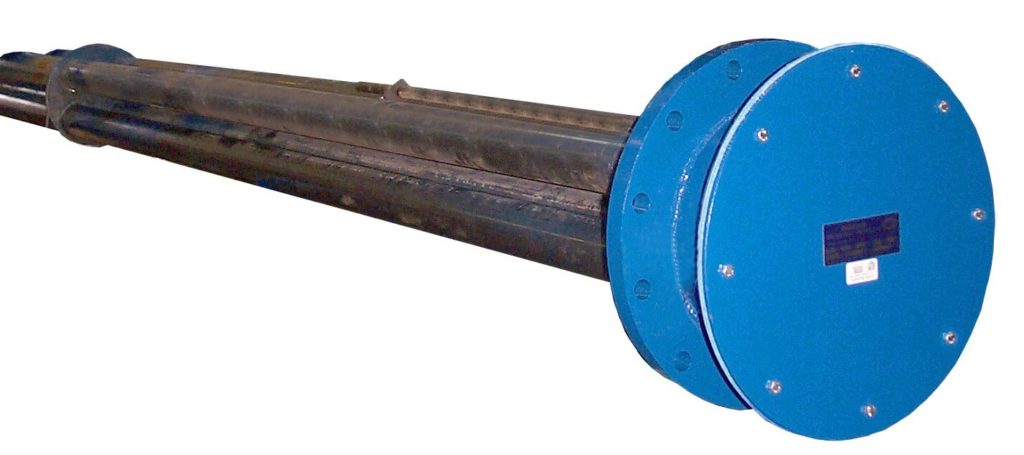

Flanged Immersion Heaters

Process Heating Company’s (PHCo) Flanged Immersion Heaters are perfect for use in tanks, large vats and reservoirs. These heaters consist of a standard 150# or 300# flange for mounting and PHCo’s exclusive heating elements. The elements are drywell style and “lo-density” design. The dry wells allow the elements to be serviced or replaced without draining the tank, a huge advantage if maintenance is required. The low watt density design keeps the element sheath temperature low, reducing the chance of coking or build up on the heater.

The flange and heater tubes can be made of mild steel or various grades of stainless steel depending on your application. These direct immersion heaters are virtually 100% efficient (all the energy consumed is transferred to your process) and easily controlled.

The heaters can be supplied either with our custom, U.L. Listed industrial control panels integrally mounted and wired to the heaters or without if controls are already present. Flanged Immersion Heaters are one of the most widely used methods of heating liquids. PHCo offers many advantages over traditional style tubular elements.

Flange/Heater Materials

mild steel and various grades of stainless steelM

Sheath Thickness

up to .300´´ wall thickness for durability and corrosion resistance

Flange Sizes

3´´ up to 36´´, 150# or 300# ANSI RF or FF

Kilowatt Ratings

up to 1,000 kW

Voltages Available

up to 600 VAC, single or 3 phase

Immersion Length

up to 40 feet

Watt Densities

up to 20 watts per square inch, less than 10 is standard

Open Coil Elements

Pipe insert type, dry well elements for ease of service

Terminal Enclosure

Moisture resistant standard. Some sizes available as explosion resistant