Lo-Density® Unitized Storage Tank Heater

Cost-Effective Choice, with Applications for:

- Asphalt/Construction

- Emulsions

- Oil Recycling

- Lube Oils

- Grease

- Oil Additives

Unique Lo-Density® drywell-style heaters dissipate controlled heat as low as three watts per square inch on the heater’s sheath to prevent coking or damaging of temperature-sensitive materials – eliminating the need to drain and clean the tank. Temperature-sensitive materials are those that experience damage when too much heat is applied to them too quickly, such as asphalt or emulsions. These products need to be heated by a carefully controlled system that reduces their viscosity for ideal application.

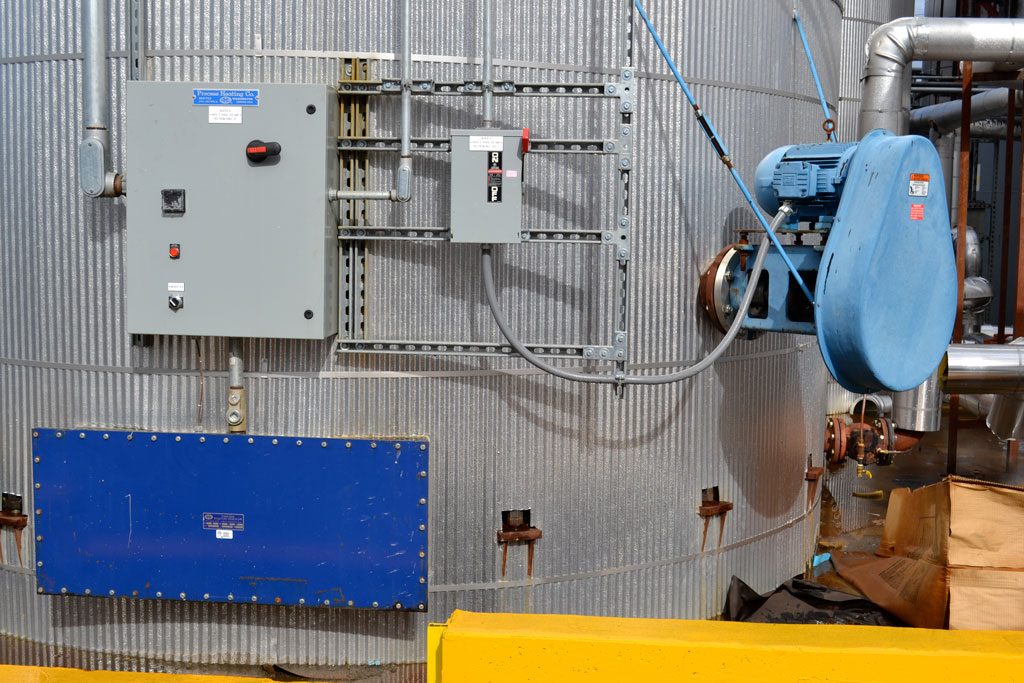

Unitized heating systems allow customizable dimensions, and are designed for easy installation into horizontal or vertical tanks/vats. The heater is installed by cutting a rectangular opening near the bottom of the tank, sliding the heating element and UL-listed control panel assembly into place, and welding the unit until it is sealed liquid-tight. PHCo heaters are far less trouble to install than coils for steam or heat transfer fluid, because they are direct-immersion heaters. No additional energy source is required. Simply hook them up to your utility or gen-set power.

With fluctuating energy prices, efficiency becomes critical to the cost of doing business. Electric heat offers 100% energy efficiency throughout the lifetime of the heater, since all of the energy is used to heat. This is compared to the inefficient burning of fossil fuels, which operate at only 85% efficiency when new—and that efficiency quickly drops to 50% to 65% over time. PHCo electric heaters typically last for more than 30 years, providing 100% efficient heat over their entire lifetime without incurring the capital cost created by replacing fossil-fuel-fired heaters every 8 to 10 years. Unitized Heaters can also be interfaced and coordinated with other electrical equipment, so the load of the heaters can be reduced to base rates, preventing increased demand charges or peak-use rates and lowering consumption cost.

Process Heating Company stands behind its equipment, offering an industry-exclusive five-year element replacement guarantee. They require no maintenance other than an annual checkup.

Lo-Density® Technology

All heaters are built with our Lo-Density® design to eliminate the possibility of coking or damaging your temperature-sensitive products. Heating elements carry our standard 5-year replacement guarantee, and are listed by ETL.

Drywell Design

Heating elements are installed in drywells, making them accessible from outside the tank and eliminating the need to drain it when servicing the elements.

Environmentally Friendly

No burners. No fossil fuels. No stacks to monitor for emissions. No air-quality or boiler permits to worry about.

UL-Listed Controls

Operation is completely automatic. The main indicating temperature control regulates the discharge product temperature. A high-limit control is included for safety. Main disconnect and individual fused heat circuits provide overcurrent protection. All components are mounted and prewired in a NEMA Type-4 enclosure.

Heater Materials

Mild steel and various grades of stainless steel.

Sheath Thickness

Up to .300-inch wall thickness for durability and corrosion resistance.

Kilowatt Ratings

Up to 1,000 kW.

Watt Densities

Up to 20 watts per square inch; less than 10 is standard.

Voltages available

Up to 600 VAC, single- or 3-phase.

Immersion length

Up to 40 feet.

Terminal enclosure

Moisture-resistant standard. Some sizes available as explosion-resistant.

Open coil elements

Pipe-insert-type, drywell elements, for ease of service.