Lo-Density® Rigid Tubular Heater

The Cost-Effective Choice, with Applications for:

- Oil Recycling, Lube Oils

- Grease, Emulsions

- Oil Additives

- Biofuels

- Asphalt/Construction

- Food Production

- Ink Manufacturing

- Pulp and Paper

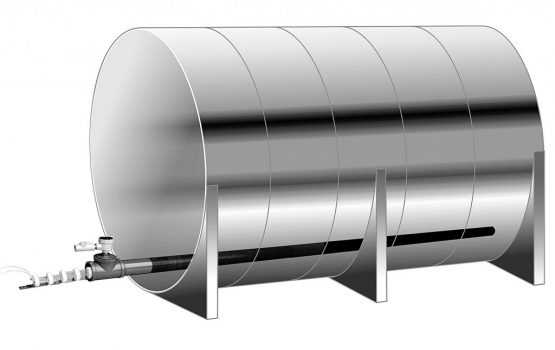

At Process Heating Company, we have developed our Rigid Tubular Drywell Heaters to provide a pre-determined Lo-Density® low-watt-density heat, dissipating low temperatures on the sheath, and gently raising the temperature of the material. These heaters will heat viscous products without damage to the product being heated or buildup on the elements, providing longer heater life.

The Rigid Heaters can be installed as new or as replacement equipment for existing metal sheathed-style tubular units in tanks or vats, and are an ideal choice versus designs that have higher watt density, which result in coking of the product. They are typically used to maintain process temperatures during operation, plant maintenance shutdowns, or to increase oil temperatures prior to startups.

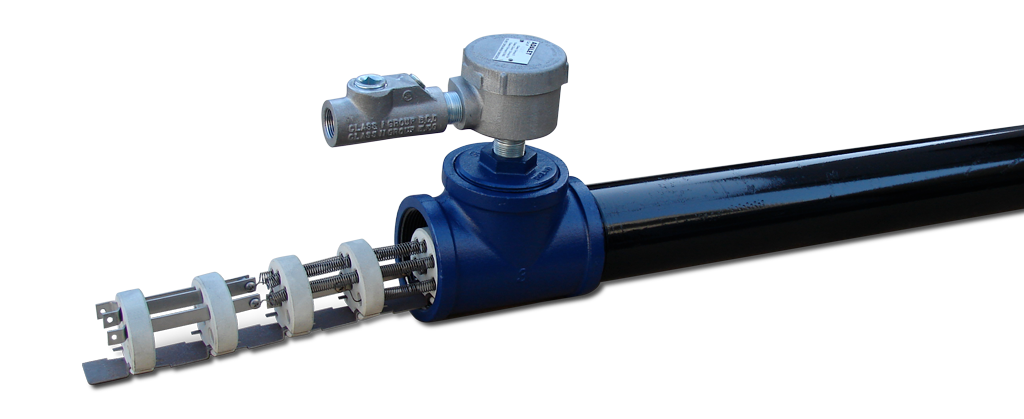

PHCo Rigid Heaters ease maintenance with their drywell design. Once installed, the flexible heater elements are removable from heater tubes for maintenance or replacement without the need to drain the tank or disconnect fluid lines, reducing plant downtime.

These heaters can be equally spaced across the base of reservoirs or around tanks for even heat distribution, eliminating hot and cold sections.

We are renowned for standing behind our equipment, offering an industry-exclusive 5-year element replacement guarantee. Our heaters require no maintenance other than an annual checkup.

Installation options

Can be installed in new equipment or as retrofits in existing tanks, vats, or reservoirs.

Versatility

Maintain temperatures in reservoirs during operation and shutdowns, or raise temperatures before startup.

Low-Watt-Density Design

Low element temperatures reduce damage or coking of fluids.

Easy Maintenance

Drywell design allows element replacement without draining the reservoir.

Heat Distribution

Low-watt-density, drywell heat provides even heat distribution throughout the reservoir.

Lifecycle

Lo-Density® heaters provide service life of up to 30 years – or longer.

Guarantee

Industry-exclusive, 5-year element warranty

Industry Ratings

Heating elements are ETL-listed. Complete UL-listed control panels are available.